Product Platforms

Considering the value of Product Roadmaps combined with normalized cost and profit curves

(Post 12)

A company eyeing your startup for purchase, or venture capital representatives with technical and commercial backgrounds, will want to discuss the nature of your product development decisions and how they relate to solving your customers’ problems. They may have a hole in their product development roadmap, and they can buy your company instead pursuing the research and development, engineering, commercialization, and production introduction costs. More and more companies don’t invest in internal R&D but rely on venture capital and government funded systems to innovate and assume risks for them. This behavior reduces their risk of buying a correct, durable, sustainable, and reliable solution that meet their customer’s needs.

When this conversation happens, you will be ably equipped to discuss the future of the solution, with your Roadmaps and future generations. But you will also need to incorporate the impact of future generations on the cost projections as well.

If you look at the roadmap, you’ll see that each generation is adopting technologies, likely across multiple functions including hardware, software, process, and test and measurement. Each new technology makes improvements to meet increasing performance requirements and cost reduction pressures from competitors and consumers. There is also the inconvenience of maintaining Gross Profit Margin through generations, and control Contribution Margin [or what’s left after covering expenses (variable costs) related to production and sales], and then covering the expense of maintaining and running the business.

Product as Platform

Careful design of the product future, marketplace changes, and the product, testing, and process roadmaps naturally lead to the introduction of a platform, where each new technology brings planned improvements and meets customers’ current and future demands. A platform expects the orderly inclusion of future technologies, even when future technologies are murky.

Back in Post 5 [link], we explored the concept of Normalized Cost, and the effects of time and the product life cycle on cost and profit. I introduced this diagram showing how normalized cost typically decrease over the phases of the product life cycle, while the profit margins increase. Both curves change drastically once product retirement phase is reached.

Now that we are visualizing the product as not just a single entity but actually a platform for ongoing improvements and future generations, let’s consider the impact of these future generations onto our Normalized Cost and Profit curves.

Product Roadmaps contrasted to Generational Normalized Cost and Profit

A successful platform design results in a decreasing normalized cost per unit and maximized profit margins over the life of the product platform (not just the Gen 1 product).

Intrinsic Cost

While I don’t want to spend a lot of time on a new concept, it’s worth discussing. The new concept is one that I call Intrinsic Cost, which has to do with Normalized Cost. A generation’s normalized cost is not set, but is related to the roadmap, design, and process decision at the generation’s inception (called this the design direction). It has been said the 80% of a product’s normalized cost is designed in from day one. As one gains experience in product development, you’ll understand that engineering solutions can swing from the mechanical domain to the electrical domain to the firmware/software domains to the controls/metrology domain, and back again. It’s a matter of dollars and cents, available technologies, and forecasted production volumes to solve problems the customers want solved, on time and at cost (this then extends to price).

Normalized Cost based on Roadmap and Product Life Cycle Decisions

Above is an example of three normalized costs to achieve the same customer experience.

Normalized Cost 1 relies on leveraging a lot of legacy design and supply chain resources, basically making software improvements and some minor usability changes; it always has the highest cost but has the shortest time to market.

Normalized Cost 2 made several improvements in software and performance because of available low-cost processors and memory upgrades, and tapped into some supplier improvements to lower hardware costs.

Normalized Cost 3 does it all, abandons platforms and invests in new hardware and software, but it takes longer than Normal Cost 2’s design direction to achieve lower costs, and costs more, longer because of developing a new supply chain and production capabilities, and requires the highest production volumes to offset all these investments.

The lowest normalized cost is not always the best intrinsic cost target. For example, to achieve Normalized Cost 3 is based on technology and development efforts that will take the same time as a competitor to introduce two generations. Hence, the lower cost may not be worth the opportunities lost. Or if the production volumes are moderate and the planned product life cycle is shorter, maybe choosing the design direction of Normalized Cost 2 is correct. If you’re trying to hold a market position until a new platform is ready, Normalized Cost 1 is the safer route.

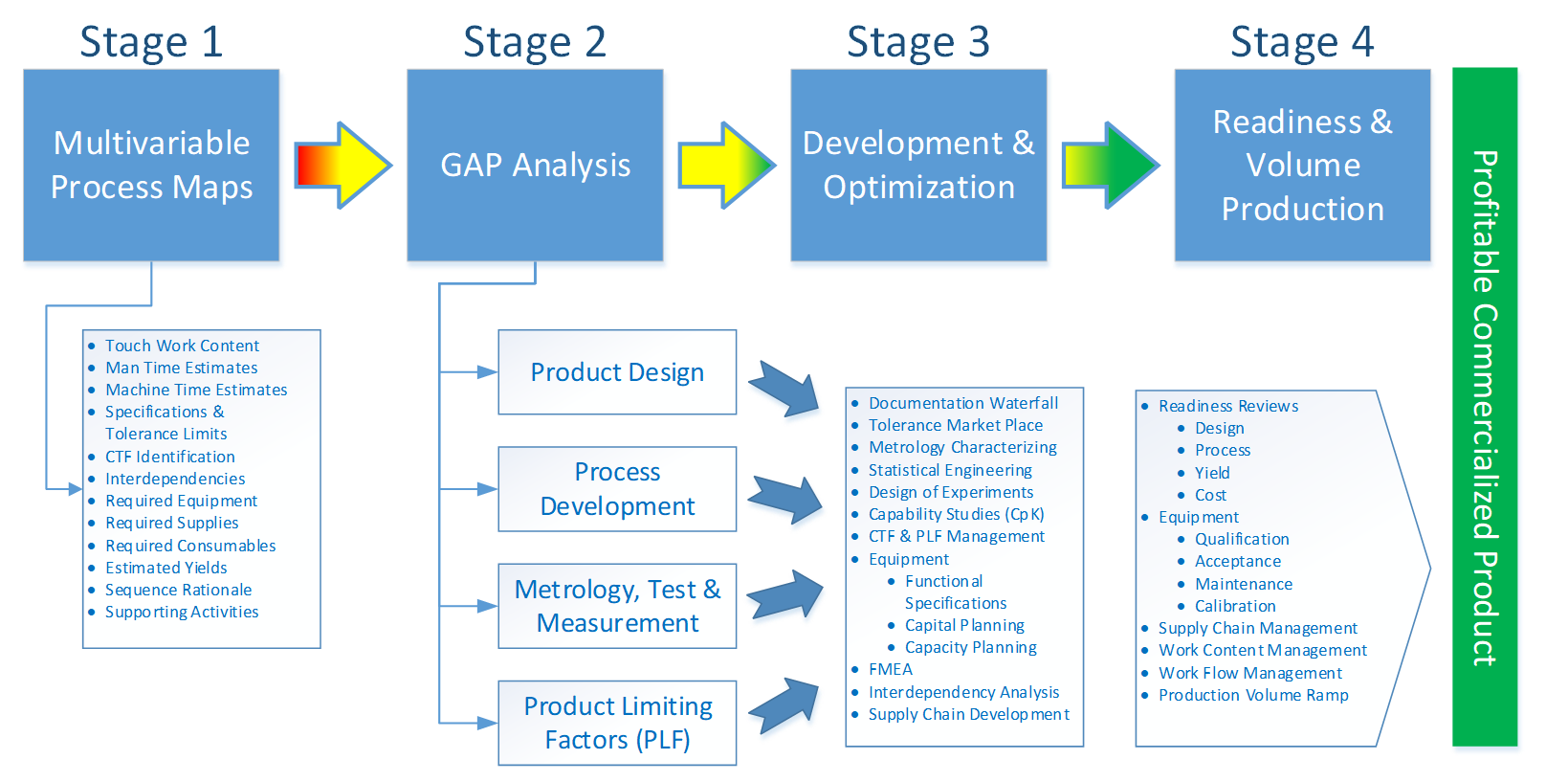

At this point you must be wondering what happened to my beloved process maps. I’ve not forgotten them, and upcoming entries will dive into the next steps in using them. I figured that readers would want some exciting background on why I always start with process maps. The basic premise is that without someone in the organization thinking about design direction, normalized cost, and the eventual chosen intrinsic cost to meet market demand at cost (price and profit) and ensuring the shortest Time to Profit, your hard-tech product will lack what it takes to make it to commercialization and profitability.

Full Arc Posts Table of Contents

Post 4 - Defining Product Requirements

Post 5 - Exploring the Product Life Cycle

Post 6 - Understanding Risks in Real Time

Post 7 - A Deep Dive on Process Modeling

Post 10 - Looking into the Future

Post 11 - Keeping an Eye on The Next Generation

Post 12 - Product Platforms